Rare Earth Alloy Series–Magnesium-Zirconium Alloy(Mg-Zr)

Specification: Mg-Zr10、Mg-Zr20、Mg-Zr30

Size: 300×100×65(mm), and customization

Shape: Waffle cone, and customization

Implementation Standards: HB 6773-1993, Hunan Rare Earth standard

Packaging Method: inner lined with plastic bags, protected by argon gas, packed in iron drums, 50kg per drum

Specification:

|

Grade |

Zr |

The impurity content shall not exceed (ppm) |

Standard |

|||||

|

Fe |

Si |

Cu |

Al |

Ni |

Mn |

|||

|

MgZr 25 |

≥25 |

0.6 |

0.17 |

0.05 |

0.1 |

0.05 |

0.1 |

HB 6773-1993 |

|

MgZr 30 |

≥30 |

0.7 |

0.17 |

0.05 |

0.1 |

0.05 |

0.1 |

|

|

Mg-Zr10 |

10±1 |

0.1 |

0.1 |

0.005 |

0.02 |

0.005 |

0.01 |

Hunan Rare Earth standard |

|

Mg-Zr20 |

20±2 |

0.1 |

0.1 |

0.005 |

0.02 |

0.005 |

0.01 |

|

|

Mg-Zr30 |

30±2 |

0.1 |

0.1 |

0.005 |

0.02 |

0.005 |

0.01 |

|

Product Applications:

1. Grain Refinement: Zirconium has a lattice constant similar to that of magnesium and can serve as a heterogeneous nucleation core to promote grain refinement, which is the most effective grain refiner for rare - earth magnesium alloys. This refinement effect can significantly improve the yield strength, fatigue resistance, and notch sensitivity of magnesium alloys, while also enhancing their heat resistance.

2. Performance Optimization: The addition of zirconium can inhibit grain growth and reduce the harm of impurity elements (such as iron), thereby improving the comprehensive performance of magnesium alloys. For example, magnesium alloys containing zirconium can still maintain good mechanical properties at high temperatures, making them suitable for high - strength and heat - resistant applications.

3. Industrial Applications: Zirconium is often added to magnesium alloys in the form of master alloys (such as magnesium - zirconium master alloy) to reduce the risk of element burning loss and improve the efficiency of grain refinement. This method helps to balance the temperature of the alloy liquid and the solubility of elements, ensuring stable performance.

Technical Advantages:

1. The preparation process is environmentally friendly and has high production efficiency.

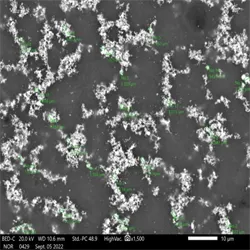

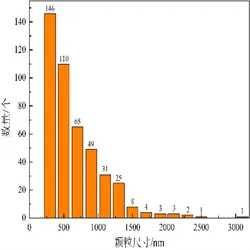

2. Zirconium particles are uniformly and dispersedly distributed in the magnesium matrix without agglomeration. The proportion of zirconium particles with a size of less than 3μm is ≥95%. The product has high purity, no molten salt inclusions, good corrosion resistance, and can be stored naturally for a long time.

EN

EN NL

NL FR

FR DE

DE JA

JA KO

KO PT

PT RU

RU ES

ES TR

TR