Magnesium wrought alloy series: Overview of High-Strength Magnesium Alloy MB25 for Extruded and Forged Components

Table of Contents

I. Introduction

MB25 is a high-strength deformation magnesium alloy of the Mg-Zn-Zr-Y series. It is usually supplied without heat treatment, either in the state of hot extrusion or hot forging, but it can also be used in an artificially aged state. It is mainly used for processing extruded products and die forgings. The tensile strength at room temperature, yield strength, and high-temperature instantaneous strength of this alloy are all superior to those of the high-strength magnesium alloy MB15.

The plasticity, toughness, and corrosion resistance of MB25 are similar to MB15. However, its process plasticity is poor at room temperature and good at high temperatures, which means pressure processing and forming must be carried out under heated conditions. MB25 has good cutting performance but poor welding performance, so it is not recommended for welded parts. It can replace some medium-strength aluminum alloys in stressed components.

II. Chemical Composition and Properties

In the air environment, MB25 alloy is prone to oxidation, and the oxide film formed on the surface is not dense and cannot provide effective protection. However, the stress corrosion tendency is small. After oxidation treatment and protective coating, it can work reliably in air environments.

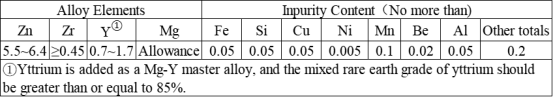

Chemical composition and impurity content (mass fraction) of MB25 alloy (%)

III. Stress Corrosion Resistance

The stress corrosion resistance of MB25 alloy material is generally stable, ensuring safety in engineering applications.

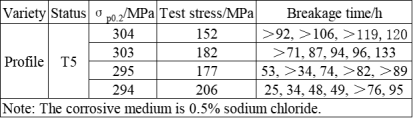

The stress corrosion resistance of MB25 alloy material

IV. Mechanical Properties

The room temperature hardness of MB25 alloy is not less than HBS65. The main mechanical properties are as follows:

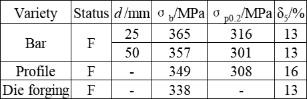

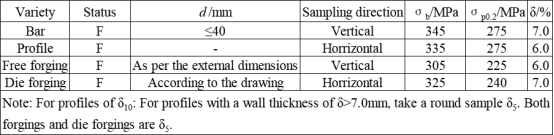

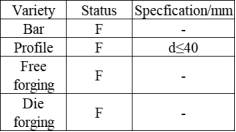

The room-temperature tensile properties of MB25 alloy material

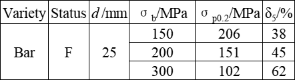

The high-temperature instantaneous strength of MB25 alloy bars

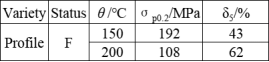

The high-temperature tensile strength of the MB25 alloy extruded profiles

The allowable mechanical property values of the MB25 alloy material

V. Process Performance

A. Forming Performance

MB25 alloy has good plasticity within the temperature range of 280–400℃. Rough forging blanks are easy to trim. When manufacturing forgings and die forgings with extruded billets, the forging temperature should be 320–390℃, and the mold heating temperature 200–300℃. For profiles, the forming temperature is 270–290℃ with a holding time of 1/4–1/2 hour.

B. Welding Performance

MB25 alloy has poor welding performance and is not recommended for welding applications.

C. Heat Treatment Process

Generally, MB25 parts are used in hot extrusion or hot forging states without heat treatment. Artificial aging can be applied: 170℃ for 10 hours followed by air cooling.

D. Surface Treatment Process

MB25 alloy surfaces require oxidation treatment followed by painting protection. To improve corrosion resistance, sealing after oxidation plus painting can be used. For storage and transport, surfaces must be protected against scratches, sealed with oil, and shielded from rain.

E. Cutting and Grinding Performance

Like other magnesium alloys, MB25 has excellent cutting and grinding performance, making it suitable for machining.

VI. Application

MB25 alloy has been technically appraised and widely applied. It has replaced some medium-strength aluminum alloys and high-strength magnesium alloy MB15 in main load-bearing components. The typical operating temperature is ≤150℃. Standard varieties, specifications, and supply forms are available in industrial production.

EN

EN NL

NL FR

FR DE

DE JA

JA KO

KO PT

PT RU

RU ES

ES TR

TR